- INTRALOGISTICS

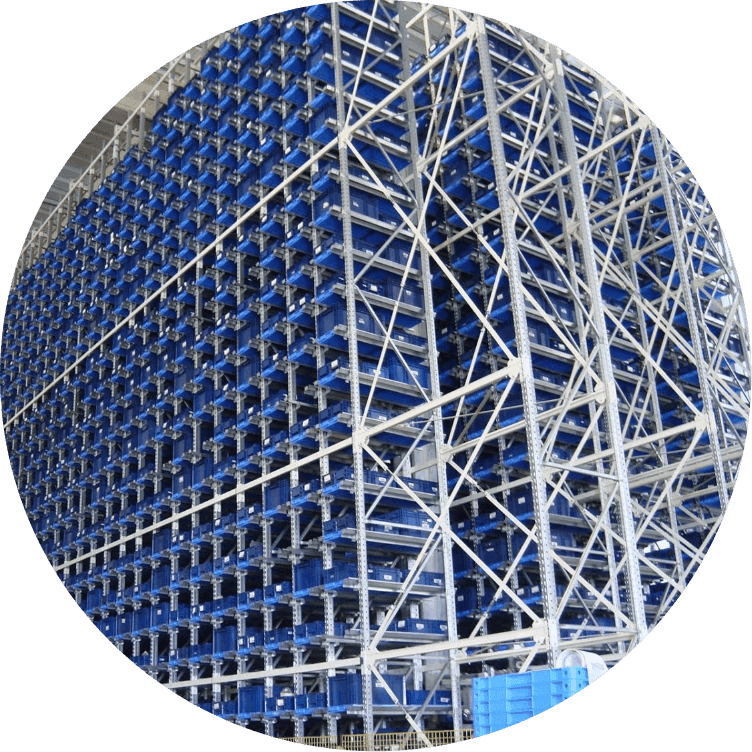

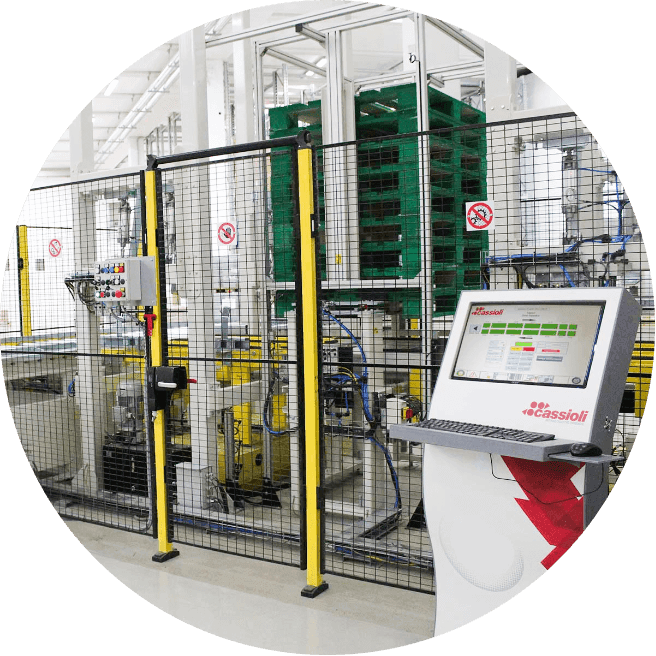

Division- Automated Warehouses

- Automated Warehouse with Stacker Crane for Pallets

- Multi-Depth Automated Warehouse with ISAT Pallet Shuttle

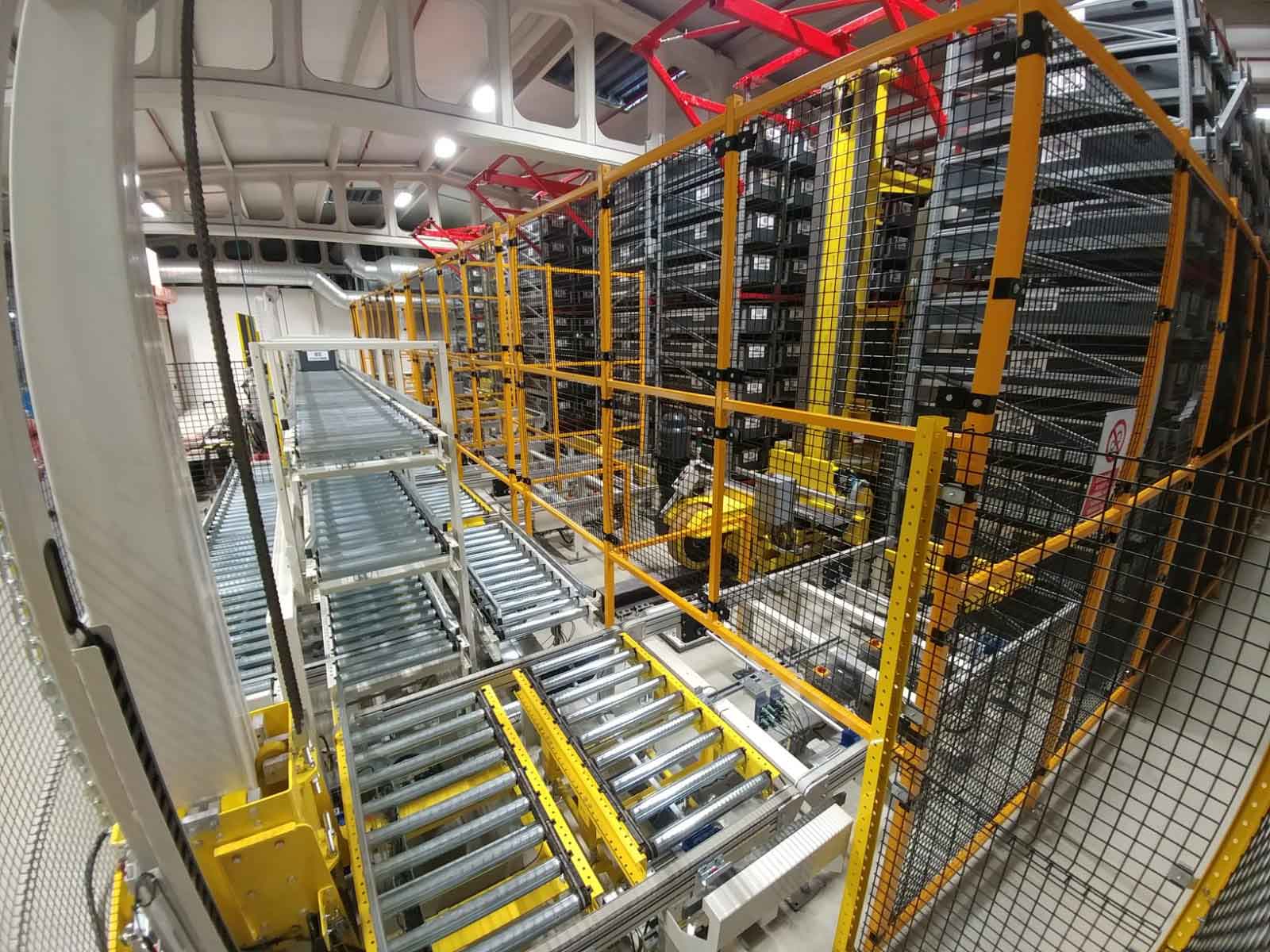

- Automated Warehouse for Light Loads

- Cartesio Vertical Automated Warehouse

- FAST Warehouse: Furniture Automatic Storage

- Special Automated Warehouse

- Automated Warehouse with Self-Supporting Structure

- Distribution centres and picking systems

- Automated vehicles

- Motorized Chain Conveyors, Belt Conveyors and Motorized and Idle Rollers

- Automated Warehouses

- TIRE

Division - AIRPORT

Division - MANUFACTURING

Division - CERAMICS INTRALOGISTIC

Division - SERVICE

Division

Menu

Menu

Menu